Surface Preparation & Coating Services

CONVENTIONAL BLASTING

As a Top Side Maintenance and Fabric Maintenance contractor, we provide dry abrasive blasting using a variety of natural mineral abrasives, including Almandite Garnet, Fused Aluminium Oxide, and Coal Slag. This dry blasting method is commonly employed for most conventional paint systems based on client specifications. By propelling high-speed dry air with abrasive material through the blasting nozzle, we create the necessary surface profile and cleanliness.

ALTERNATIVE BLASTING

SPONGE MEDIA BLASTING

Sponge Media Blasting represents an innovative, environmentally friendly blasting technology that uses dry, low-dust, reusable surface preparation media. This method enhances efficiency and productivity during blasting operations. It is notable for its low dust emission and the absence of silica content, ensuring safety for both users and the environment. Compared to conventional grit blasting, which can produce high noise levels and dust, Sponge Media Blasting minimizes ricochet and enhances operator visibility, leading to significant project savings. This method is particularly beneficial for general corrosion projects, production-oriented facilities, unique substrates, or challenging safety environments.

WET BLAST

Wet slurry blasting involves propelling a mixture of wet abrasive material, typically garnet-based with minimal water, against surfaces under high pressure. This technique is effective for smoothing rough surfaces, roughening smooth surfaces, shaping surfaces, or removing existing coatings. Wet blasting is especially useful in sensitive, dusty environments or where a completely spark-free environment is required.

VAPOR BLAST

Vapor Blast is another alternative to Wet Blasting. It involves injecting water at the end of the blasting line, atomizing it to create a vapor shield at the blasting nozzle. This technology minimizes nuisance dust and spark risks while consuming only about 2 liters of water per minute. Vapor Blasting maximizes production and minimizes abrasive consumption in a controlled, low-maintenance, and safe manner.

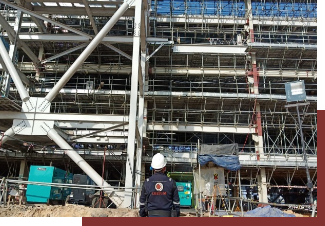

ABSEILING METHOD

To complement our blasting services, we offer professional Abseiling Method solutions for blasting and painting activities. With a certified and experienced team of abseilers, we have successfully secured and completed numerous work orders with high productivity, quality, and safety standards.