POWER AND MACHINERY

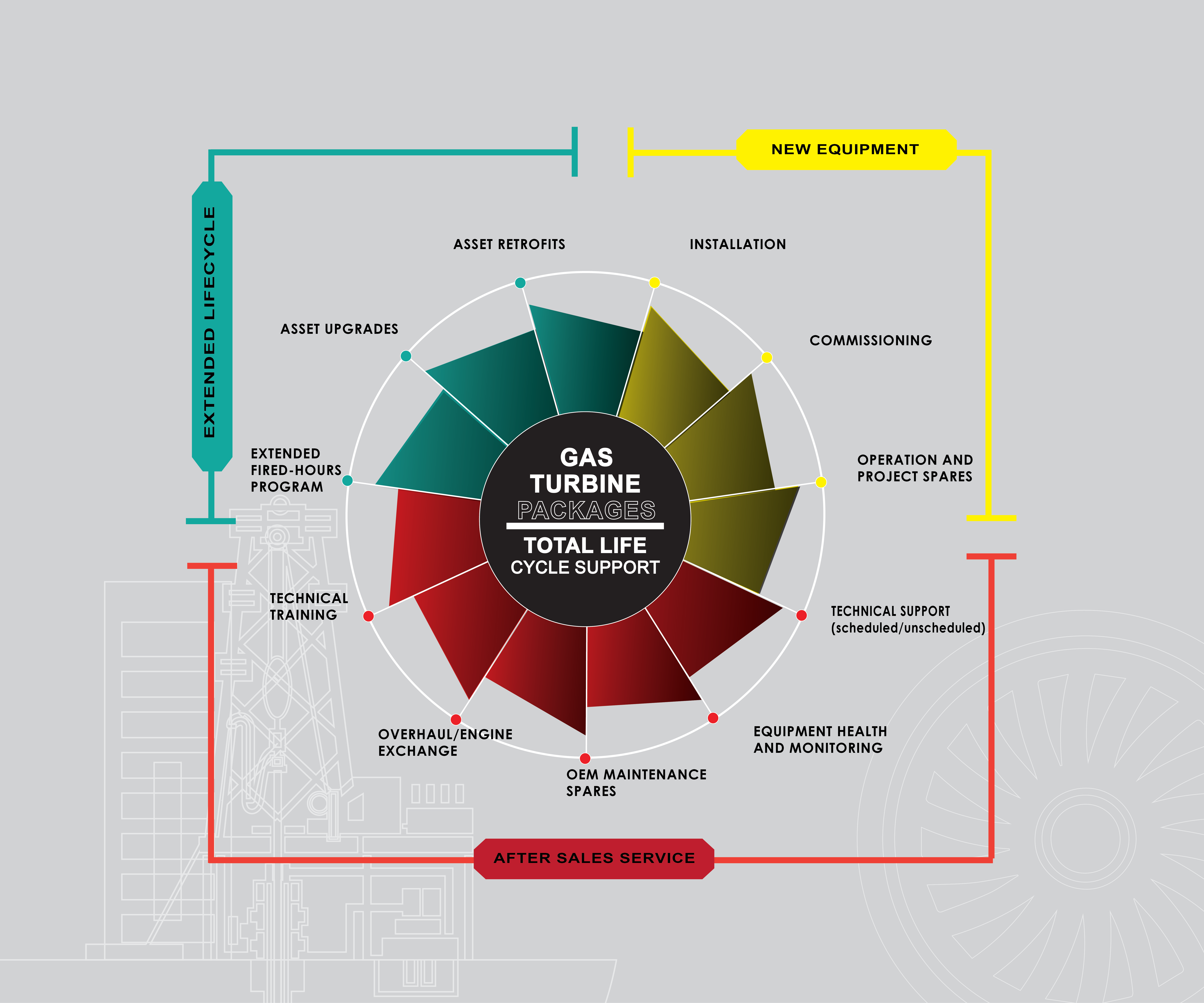

Deleum’s Power and Machinery segment focuses on the provision of a complete life cycle support of Solar Turbines’ gas turbine generators and compressor packages, turnkey solutions for combined heat and power plants; Heatric’s printed circuit heat exchanger; GASCO’s process (heat) and thermal engineering solutions; and electrical and mechanical equipment repairs and services (MRO).

With the strong business ties with our principal Solar Turbines Incorporated, the world leading industrial gas turbines producer between 1 to 23MW, Deleum is capable in providing various gas turbine applications solution to meet our customers’ requirements; such as power generation, gas compression and pumping systems, as well as gas compressors for pipeline and production.

With the addition of Heatric, a division of Meggitt, the world pioneer in diffusion bonded printed circuit heat exchanger (PCHE) in our portfolio, Deleum is capable to provide thermal solutions to complement our existing supply. PCHEs are suitable and used extensively in the processing of gas and light hydrocarbon liquids. Discharge, inlet coolers and after-coolers, CO2 coolers, dewpoint exchangers, fuel gas pre-heaters, feed water cooling or dehydration units; whatever the application, high performance comes as standard.

To complement our business, Deleum has made ties with GASCO, the leading combustion and process engineering provider. Deleum offers wide range of solutions for oil and gas, power generation, environmental, refining and petrochemical for water bath heaters, thermal oxidizers, fired heaters, thermal oil heaters, flares, waste heat recovery systems, HRSG boilers, burner management systems and gas conditioning skids fit to meet our customer’s requirements.

To further strengthen our aftermarket support, Deleum has constructed an integrated facility in Senawang that provides gas turbine overhaul and repair services. Being an integrated facility, it also serves as the regional training centre, equipped with advanced simulators and training skids. The regional factory pre-commissioning tests for package system upgrades are also being performed in this facility. The segment also oversees the supply, installation, repair and maintenance of motors, generators, transformers, pumps, valves, flow regulators and provides composite repair integrity for pipeline and structure for oil and gas as well as general industries and is focused on delivering improved performance, maintaining high reliability and availability of rotating equipment installed at customers’ asset base, both onshore and offshore.

We are also the authorised service centre for various Original Equipment Manufacturer (OEM) to support their before and after market service activities.