Other Services

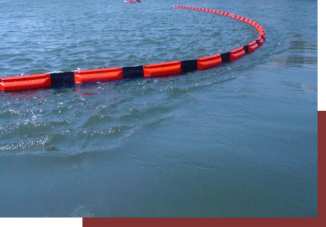

SLICKBAR OIL SPILLAGE COMBAT EQUIPMENT & SERVICES

SLICKBAR™ provides a comprehensive range of equipment for oil spill containment and cleanup, including Oil Booms, Skimmers, Absorbents, Spill Monitoring Systems, Dispersants, Sprayer Systems, Response Vehicles, and Vessels. These products and services are certified under ISO 9001:2008 for quality, ISO 14001:2004 for environmental management, and OHSAS 18001:2007 for occupational safety. With over 50 years of experience, SLICKBAR™ delivers solutions that meet the highest international standards.

In addition to equipment supply, we offer maintenance services for Oil Spill Response equipment of any brand, using certified original parts and trained response teams. Equipment rental and oil spill response teams are also available for emergency deployment.

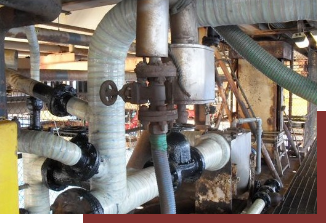

COMPOSITE WRAPPING AND REPAIR WORKS

DTSSB offers advanced composite wrapping solutions to maintain the integrity of pipework and strengthen structures. Our wrapping system uses fibers reinforced with epoxy resin (carbon or glass), customized based on the client’s needs such as temperature, pressure, and defect type. Wet layup systems applied onsite offer flexibility and durability.

Key Benefits

Corrosion-resistant with no maintenance

Live application, avoiding shutdowns

Live application, avoiding shutdowns

No hot work permit required

Minimal onsite facilities needed

Can be applied to any geometry or confined spaces

Components Repairable

Piping systems (bends, tees, etc.)

Pipelines

Vessels/tanks (shells, supports)

Caissons and risers

Walkways, handrails, roofs

Repairs cover internal corrosion, external dents, through-wall leaks, and cracks

TANK AND VESSEL CLEANING

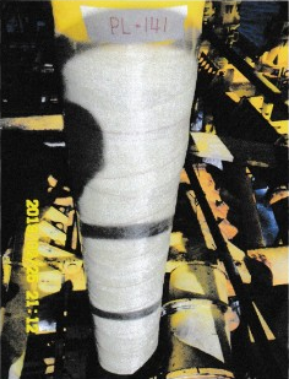

Solidsvac Solid Pump System

Our Solidsvac Solid Pump System offers an efficient and versatile solution for tank and vessel cleaning. These vacuum pumps are manufactured from 316 stainless steel as standard and are 100% air-operated for vacuum loading and pressure discharge. With no internal components, the pumps are resistant to cavitation, do not require priming, and are not affected by dry running.

The Solidsvac pumps can recover a wide range of materials from distances exceeding 50 meters and convey them up to 1,200 meters from the pump. They are capable of vertical suction lifts of over 20 meters and vertical discharges of more than 40 meters. These pumps are designed for heavy-duty operations, allowing the transfer of various materials such as drill mud or wet cement.

In addition, Solidsvac provides a range of accessories, such as the Vac-Head tool. This tool enhances operational efficiency by enabling quick recovery and transfer of drill mud from rig floors or wet cement from concrete cutting, making it an ideal choice for a variety of industrial cleaning tasks.